Partner for highest demands for more than 60 years,

for more than 30 years in Africa

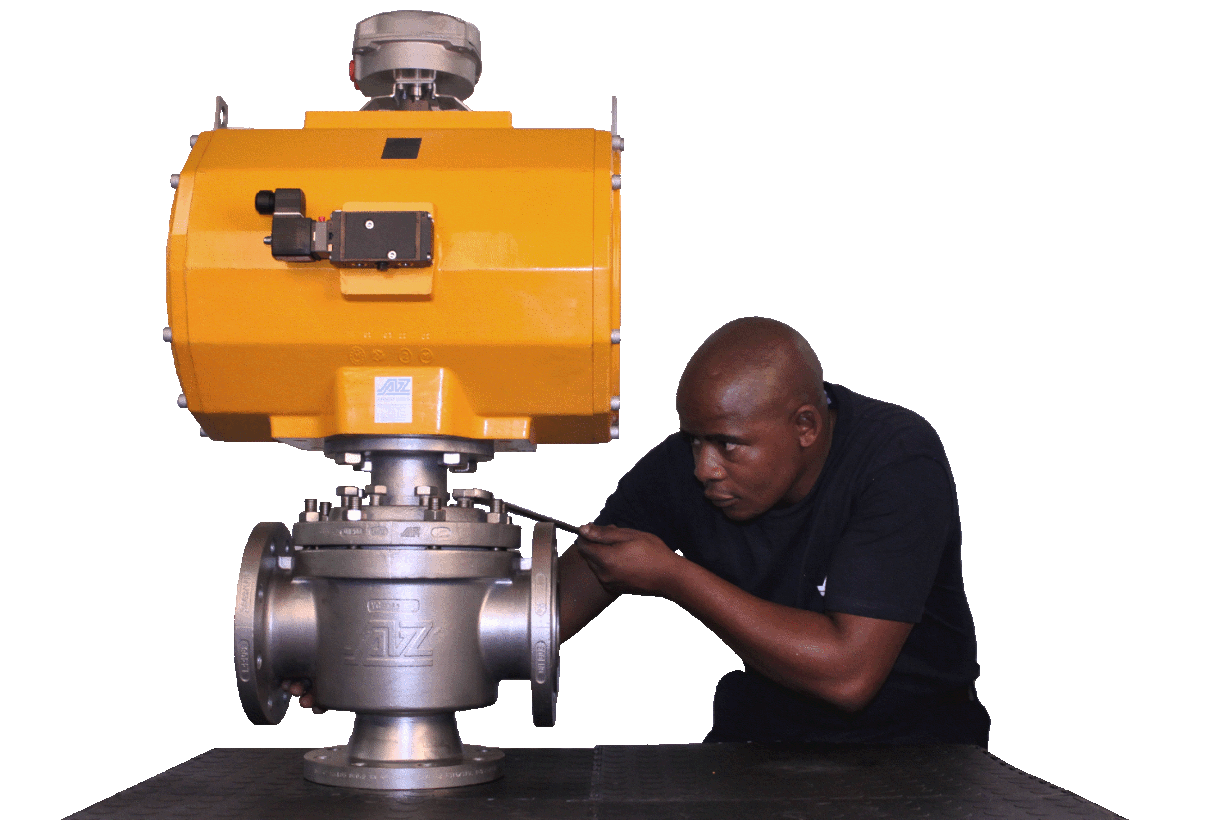

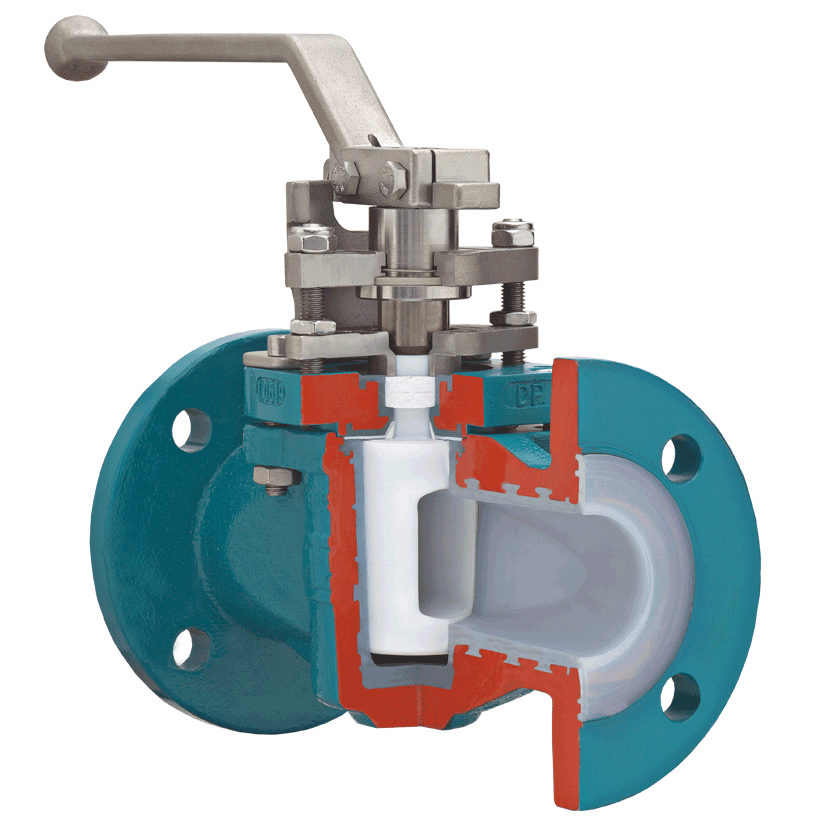

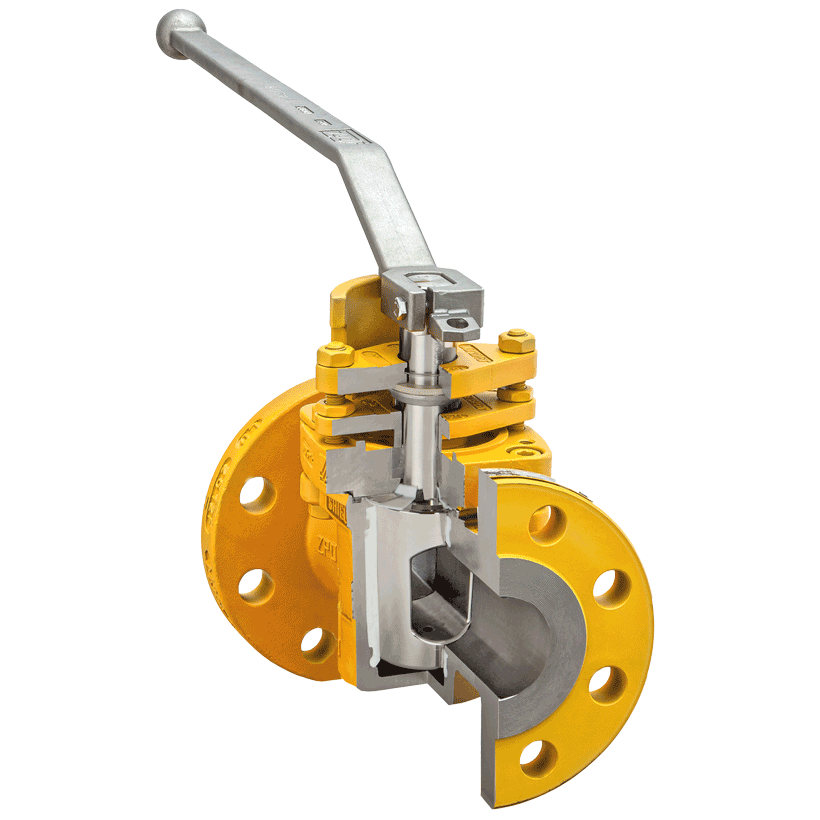

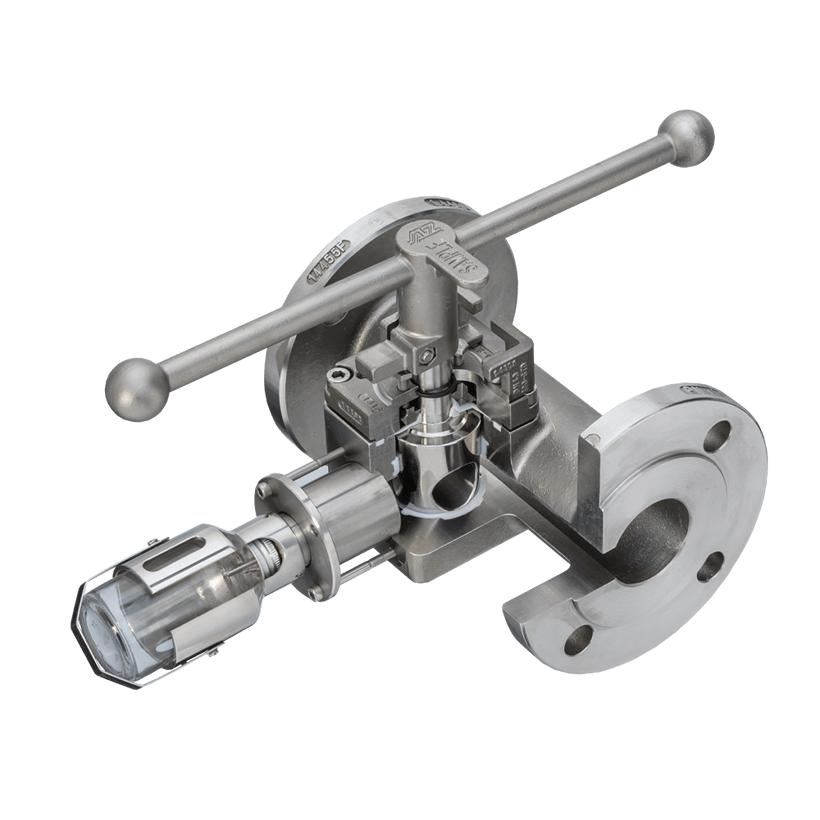

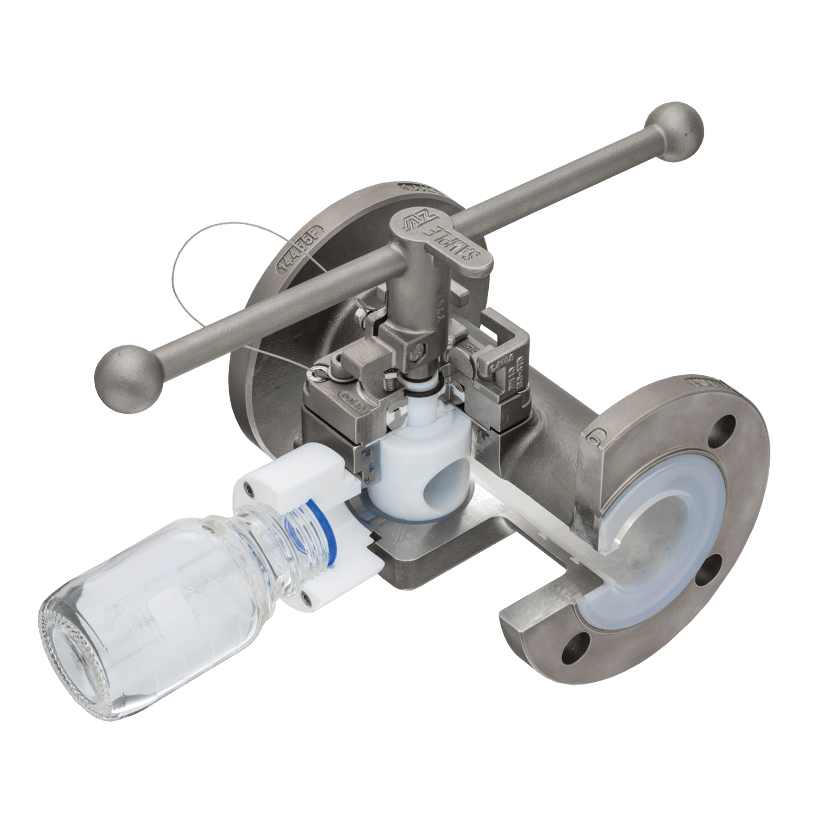

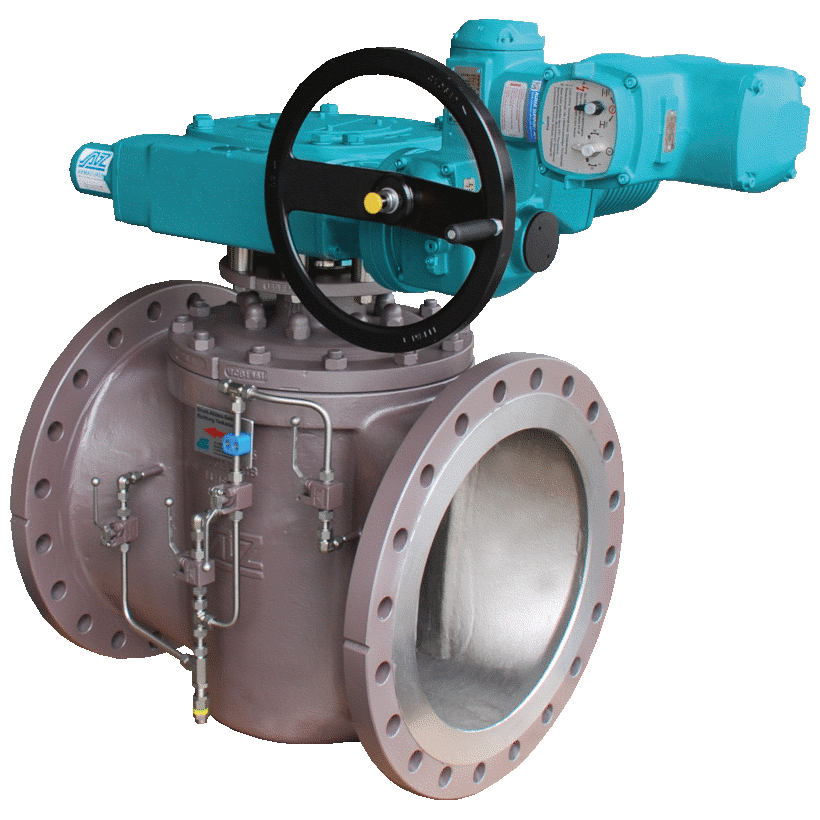

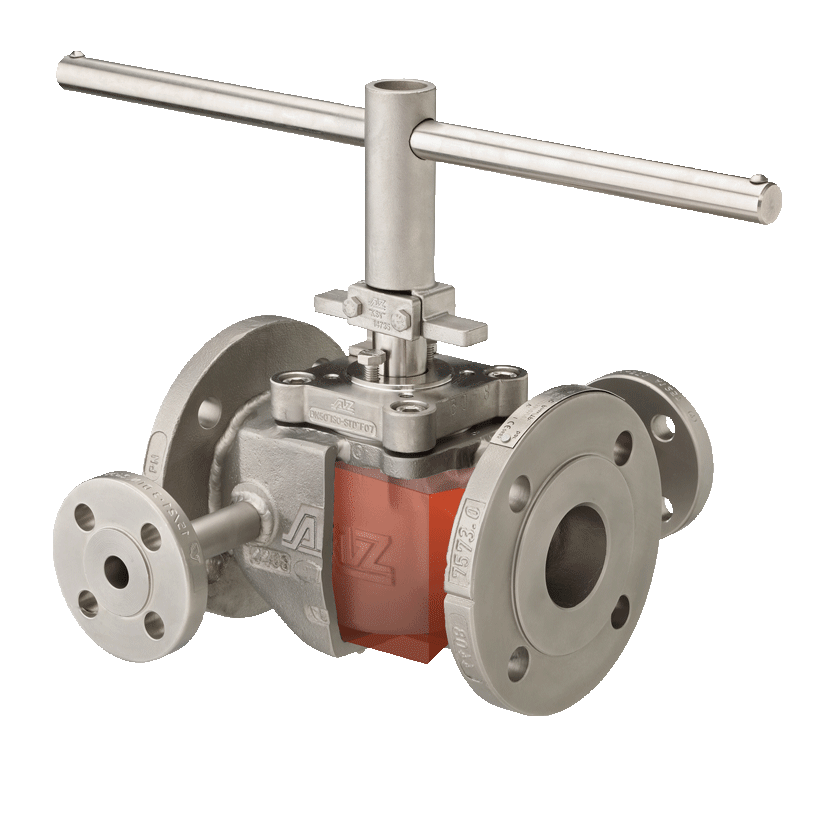

As one of the leading manufacturers of cavity free plug valves and special valves, AZ supplies to production plants in the chemical, petrochemical, pharmaceutical, paper, food industries as well as for nuclear power plants and many other areas. Special valves for highest demands in areas with high operating pressures and aggressive, toxic or abrasive media are designed and developed together with our customers.

In the 50 years of the company’s existence, AZ has continuously developed to meet the increasing requirements of customers active around the world and today AZ manufactures internationally on four continents.

AZ-Armaturen South Africa PTY LTD.

28 Derick Coetzee Street

BOKSBURG 1459

Telephone: + 27 11 3973665

Telefax: + 27 11 3973803

E-Mail: sales@az-armaturen.co.za

Website: www.az-armaturen.co.za